TECHKON ExPresso

Analysis at the press

TECHKON SpectroDrive scans print control strips on printing sheets in seconds, making it the ideal quality control solution for high-speed packaging printing. The trend towards smaller print runs, shorter delivery times and consistent color quality must be taken into account today by print service providers and packaging manufacturers in order to gain a competitive advantage. Shortening set-up times and avoiding mistakes and rejects are crucial for a satisfactory profitability.

The SpectroDrive measurement results are displayed directly on the screen using the TECHKON ExPresso 4 software, allowing printers to make corrections immediately, even before color deviations can be seen with the eye. All color measurements are made in less than 10 seconds up to 105 cm sheet width.

The program supports printing machines of all manufacturers up to a sheet size of 206 cm (80 inch) sheet width. Any print control strip with equal patch width can be used

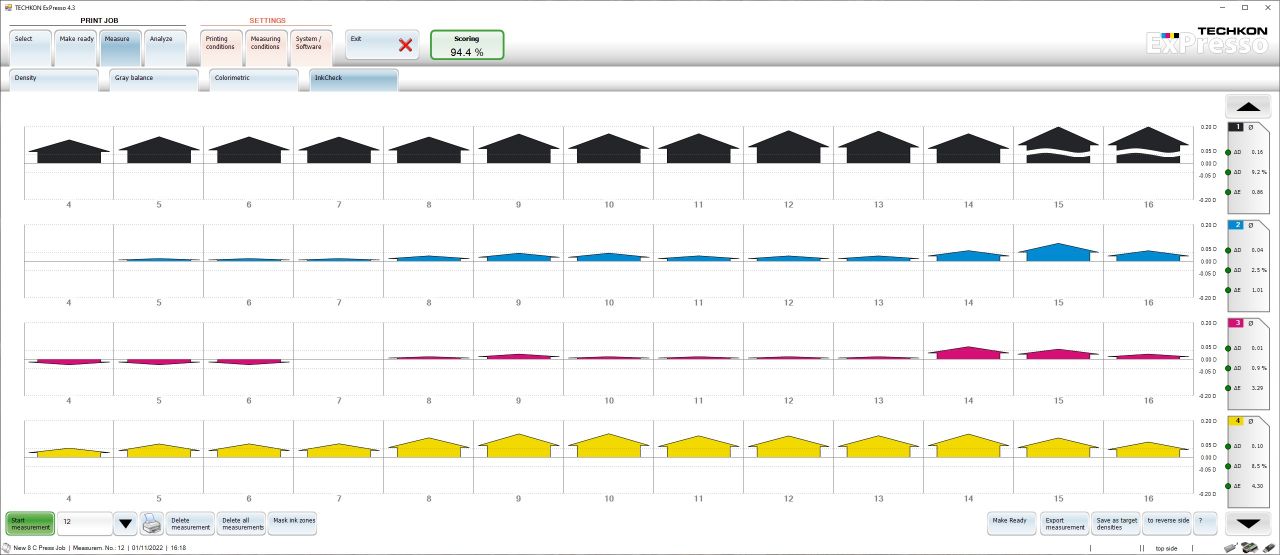

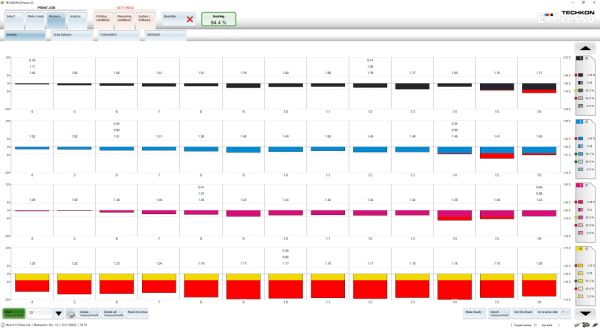

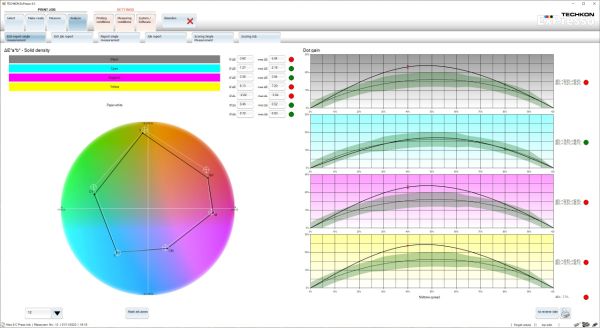

Process colors, special colors such as PANTONE®, substrate, dot gain, gray balance and density values are measured and immediately displayed clearly in ink zone specific diagrams. The range of functions of the TECHKON ExPresso 4 software includes the display of up to 16 printing units, front-side and reverse printing, evaluation according to color density, colorimetry, gray balance and calculation of the density adjustment for the lowest delta E.

The program supports key industry standards, including optical brightener M1, M3 for wet ink densities as well as ISO 12647, PSO, IDEAlliance G7, GRACoL and SWOP 2013.

The evaluation module can be used to create and print quality reports according to ISO 12647 or customer-specific standards. For a quick assessment of the entire order at a glance, a scoring with its own definition of priorities and weighting is available. Furthermore, the program now supports 16 languages for easy operation and offers touch-screen support.

All color references are managed in the color library of the software. Importing CxF3 color data is quick and easy. All job data including OK sheets are automatically stored in the integrated database, making setting up of repeat jobs a snap, allowing set up of new jobs within seconds.

The measurement data can be exported to other programs via industry standards such as JDF, for example to realize direct online connections for automatic ink key control on printing presses.